Welcome to Hamilton Labs Built Environment 3D Printing

A Collaborative, Co-Working Eco-System for 3D Printing & Industrial Additive Manufacturing in the Built Environment

A Collaborative, Co-Working Eco-System for 3D Printing & Industrial Additive Manufacturing in the Built Environment

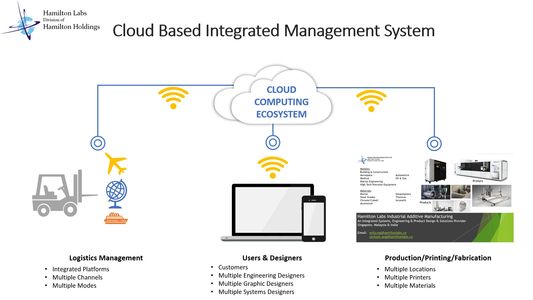

To revolutionize industrial additive manufacturing by building an eco-system that makes automation easy, scalable and accessible. Our approach is to design access to available excess production capacities through a range of technologies & methodologies with focus in 3D printing & industrial additive manufacturing.

Work with Us to Build the Industrial Additive Manufacturing Eco-System & be a Digital Champion

Curious about how 3D printing can transform the traditional Construction industry? Listen to the perspectives of key industry experts from Mighty Buildings, BASF Forward AM, Witteveen+Bos, Hamilton Holdings Pte Ltd, BESIX 3D, Eindhoven University of Technology (TU/e), Cincinnati Incorporated and Sika as they share their vision for the technology in the Future of Construction.

NAMIC's inaugural directory of companies involved in 3D Printing Technology.

Hamilton Labs is ready to facilitate, grow and lead the challenges ahead

A fully supported co-working space in which to research, design, develop and collaborate. Our exclusive community combines all the elements you need under one roof to help you create & nurture new businesses, 3D printers, eco-friendly materials, designs, software, procedures and innovations to tackle climate change and to improve lives

Hamilton Labs’ in-house engineers and designers utilize the ultimate tools in driving behavior change, reflecting Hamilton Labs’ desire to emulate the design “culture” of uninhibited brainstorming, quick stand-up meetings, and collaboration to innovate and disrupt the norm

Additive manufacturing (AM) is a transformative approach to industrial production that enables the creation of lighter, stronger parts and systems. It is yet, another technological advancement made possible by the transition from analog to digital processes. Additive manufacturing (AM) is frequently called disruptive, because it takes a bit of chaos to implement effectively.

"3D-Printing has outgrown its status as a niche technology. Being a key component and enabler of Industry 4.0, 3D-Printing evolves as a practicable alternative not only in product development but also in conventional manufacturing. Watch our video to find out more about 3D-Printing's revolutionary potential and what's in it for your business.". strategy&, Part of the PwC Network

"3D Printing has moved well beyond prototyping, rapid tooling, trinkets, and toys."

- Harvard Business Review

Benefits

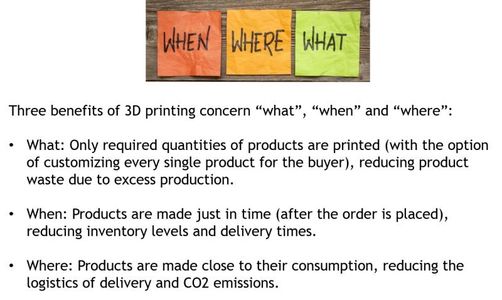

Cost: Being able to create a real product directly from a digital file takes away the need for transport costs and the labour involved.

Waste: Since every design, dimension and measurement is digitalized, there is a vast r

"3D Printing has moved well beyond prototyping, rapid tooling, trinkets, and toys."

- Harvard Business Review

Benefits

Cost: Being able to create a real product directly from a digital file takes away the need for transport costs and the labour involved.

Waste: Since every design, dimension and measurement is digitalized, there is a vast reduction in the amount of waste created in the manufacturing process. Any material left over is able to be recycled.

Specifics: There is also the ability 3D printing gives in terms of customisation and originality, with products created to exact specifications given by the customer.

Pioneering Green-Tech Innovations Through Additive Manufacturing and the Circular Economy.

The Circular Economy unites the entire supply chain, keeping resources in motion. PLUS, additive manufacturing enables completely new designs to be produced and supply chains to be significantly reduced.

3D printing has the potential to “combine the solidity, durability and strength of the industrial age, with the nimbleness, flexibility and adaptability of the virtual age.” This mix will be critical for addressing the complex challenges of a rapidly changing and uncertain world

Additive Manufacturing offers the possibility of creating hig

3D printing has the potential to “combine the solidity, durability and strength of the industrial age, with the nimbleness, flexibility and adaptability of the virtual age.” This mix will be critical for addressing the complex challenges of a rapidly changing and uncertain world

Additive Manufacturing offers the possibility of creating high-performance materials and processes with smaller carbon footprints

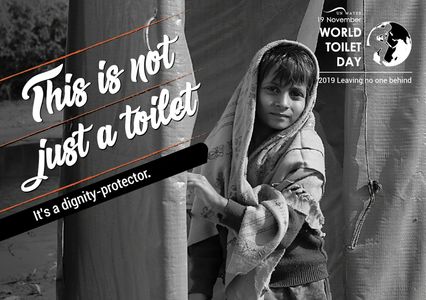

The Sustainable Development Goals was launched in 2015 to ensure everyone has access to a safely-managed household toilet by 2030. This makes sanitation central to eradicating extreme poverty.

In 2013, the United Nations General Assembly officially designated November 19 as World Toilet Day. World Toilet Day is coordinated by UN-Water in collaboration with governments and partners.

Right now, 600,000 of the world’s 1.7 million who die annually from unsafe water and sanitation (due primarily to open, unclean toilets) live in India. As billionaire philanthropist Bill Gates recently wrote on his blog, those kinds of conditions make a plan like Clean India worthy of both praise and financial support.

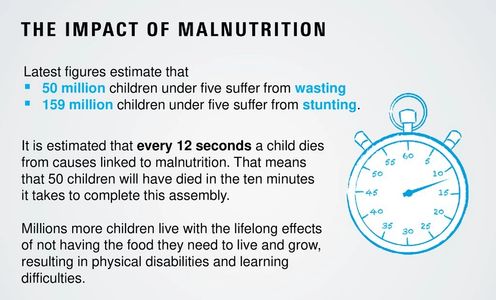

The World Bank links one in ten deaths in India to poor sanitation. From contaminated groundwater children pick up chronic infections that impair their bodies’ ability to absorb nutrients. Almost 44 million children under five, says the bank, have stunted growth, and every year over 300,000 die from diarrheal diseases.

Climate change is the greatest environmental challenge facing the world today. It is essential that we act now by reducing emissions and product waste and by adapting to change.

Now, we are set to tackle specific problems like CO2 emissions and climate change

Tackling Climate Change Through a Circular Economy

A circular economy is an economic system aimed at eliminating waste and the continual use of resources.

Copyright © 2023 Hamilton Labs - All Rights Reserved.

Powered by GoDaddy